Safety classification and difference of safety light curtain

22 Oct 2024 click : 1353

22 Oct 2024 click : 1353Safety light curtain is generally used in the areas and scenes that need to be protected to prevent automatic machinery from causing harm to the human body. In fact, the safety light curtain belongs to the photoelectric products, through the emission and acceptance of two parts, the safety level is generally SIL 1 (type 1 light curtain) or SIL3 (type 2 light curtain), so where is the difference between them?

As shown in diagram

|

Features |

Type1 |

Type2 |

|

Control reliability |

Check for faults during startup or restart |

Continuously monitor your own faults |

|

Effective aperture angle |

5° EAA. When the light curtain is installed close to the reflective surface, there may be an unsafe alternative path, the so-called optical short circuit. |

2.5° EAA. A more compact effective aperture Angle reduces the risk of optical short circuits. |

|

Redundant circuit |

no requirement

|

This includes replicating critical components and circuits to provide a backup system if the primary system fails |

|

Achievable level of security |

SIL cl 1 and PLC |

The highest attainable safety levels required to meet the requirements of IEC61496: SIL cl 3 and PL e |

|

Cost |

lower cost |

Usually the cost is higher, but the ifm Type 2 light screen price is comparable to the Type 1 light screen price |

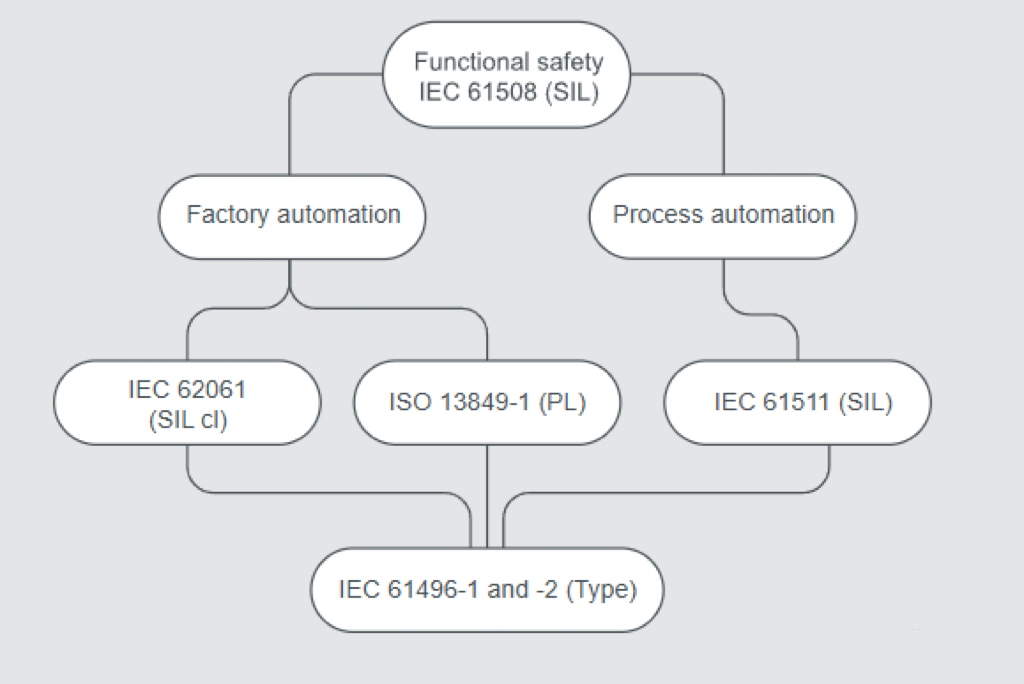

What are the standards for safety features?

1. IEC 61508: This is an international standard that defines functional safety requirements for electrical, electronic and programmable electronic devices. It defines how systems are designed, operated, and maintained to achieve a specific level of safety integrity (SIL). Other industry-specific standards are often based on or referenced by this standard.

2. ISO 13849-1: This standard defines performance level (PL) requirements for the electrical, electronic and programmable electronic equipment of machines. It focuses on how these devices can be applied on machines to ensure safety.

Simplified description: ISO 13849-1 provides a performance standard for safety equipment for machines.

3. IEC 62061: This standard defines Safety Integrity Level Declaration (SIL cl) requirements for electrical, electronic and programmable electronic equipment and non-electrical machinery (such as hydraulic and pneumatic devices).

Simplified description:IEC 62061 provides measures of safety performance for different types of equipment and systems.

4. IEC 61511: This standard defines safety integrity Level (SIL) requirements for process automation. It has a particular focus on automation systems used in the chemical, petroleum and other process industries.

Simplified description: IEC 61511 ensures that the safety performance of process automation systems reaches a predetermined level.

5. IEC 61496-1 and -2: These standards specifically address optoelectronic devices such as light curtains and gratings, defining their requirements and test methods. These devices are often used to ensure secure interactions between people and machines.

Simplified description: IEC 61496-1 and -2 ensure that the safety performance of optoelectronic devices, such as light curtains, meets predetermined standards.