What is a standard safety light curtain?

15 Dec 2023 click : 295

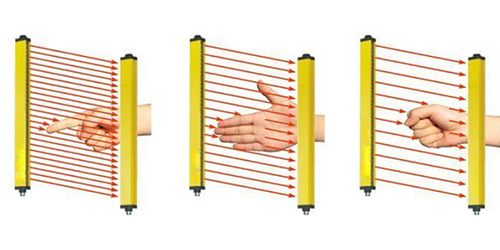

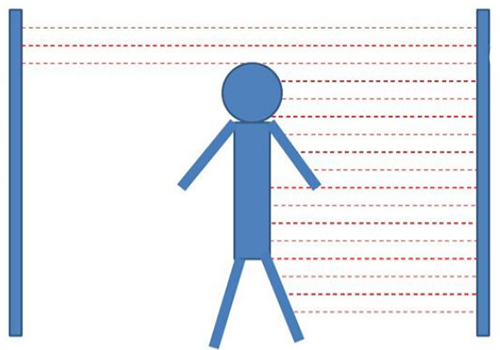

15 Dec 2023 click : 295Safety light curtain is a common photoelectric protection device, used to realize the safety protection of mechanical equipment. It detects whether the object enters the set protection area through the transmission and reception of infrared beams, thus realizing the timely protection of mechanical equipment. Safety light curtain is widely used in automation equipment, robots, logistics conveying line and other occasions, for industrial production to provide higher efficiency and safer protection.

Generally speaking, the specifications and standards of safety light curtains include the following aspects:

1. Grating length: the length of the safety grating refers to the distance between the infrared beam emitter and receiver, usually in millimeters (mm). Different application scenarios require different lengths of safety light grating, so you can choose the right length according to your specific needs.

2. Beam spacing: beam spacing refers to the distance between each beam of the grating, such as 5mm, 10mm, 20mm, 40mm. Different beam spacing can protect different objects, we can choose according to the specific use of the environment and equipment requirements.

3. Protection area: protection area refers to the safety grating can effectively monitor and protect the scope of the region. Usually can be divided into vertical protection and horizontal protection of two directions, can also be customized according to specific needs, such as multi-area protection.

4. Response time: the response time of safety light grating refers to the time interval after the grating receives the object into the protection area and sends out the alarm signal. Usually in milliseconds (ms) as a unit, for the application of the need for rapid response, the response time requirements are lower.

5. Safety level: the safety level of safety grating refers to the protection performance and safety level it can provide. According to international standards and relevant regulations, safety light grating is usually categorized into different grades to suit equipment with different levels of danger.

In addition to the basic specifications and standards listed above, safety light curtain should also meet some specific performance requirements and testing standards to ensure their stable and reliable operation. For example, the safety light curtain should have the ability of anti-interference, can adapt to the strong light, vibration, temperature change and other environmental factors.

In the selection and use of safety light curtain, also need to consider some other factors, such as installation mode, communication mode, protection distance adjustment. At the same time, users should also pay attention to the daily maintenance of the grating, such as regular inspection and cleaning, timely replacement of aging parts, etc., to ensure that the safety curtain is always in good working condition.

.jpg)