Safety light curtain common problems and repair methods

29 Dec 2023 click : 1990

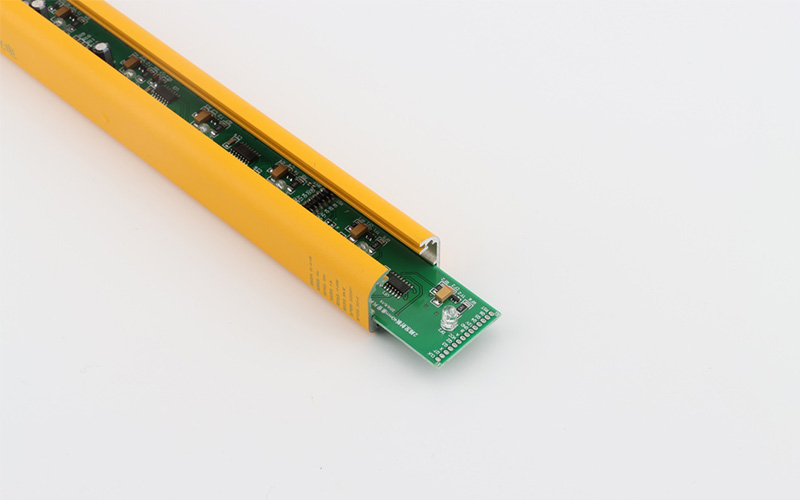

29 Dec 2023 click : 1990Safety light curtains are commonly used in industrial settings to ensure the safety of operators by detecting and preventing access to hazardous areas. However, they can experience certain problems that may require repair.

Here are some common safety light curtain failures that may occur and how to repair them:

1. Inaccurate sensing:

POSSIBLE CAUSE: The light beam in the grating is blocked, possibly due to dust, grease, water droplets, etc.

REPAIR METHOD: Clean the emitter and receiver of the grating to ensure that the beam can travel freely. Check that the mounting position is suitable to avoid reflection, deflection or obscuration.

2. False or fake alarm:

POSSIBLE CAUSE: The grating is affected by external light sources, such as sunlight, strong light sources, etc.

REPAIR METHOD: Adjust the position of the grating, use a light shield or other methods to prevent the influence of external light sources. Ensure that the grating is not affected by reflective objects.

3. Electrical fault:

POSSIBLE CAUSE: Poor cable connection, damaged cable, poor contact, etc.

REPAIR METHOD: Check cable connections to ensure they are secure. Check cables for damage and replace if necessary. Check if the connector is clean and working properly.

4. Mechanical damage:

POSSIBLE CAUSE: Damage to the physical parts of the grating, e.g., bracket, housing, etc.

REPAIR METHOD: Check the mechanical structure to ensure that the bracket and housing are intact. If damaged, repair or replace the damaged part.

5. Power supply problem:

POSSIBLE CAUSE: Unstable power supply voltage, power supply failure.

REPAIR METHOD: Check whether the power supply voltage is stable, if there is any problem, you need to adjust or replace the power supply. Make sure the power supply line is well connected.

6. Photoelectric element malfunction:

POSSIBLE CAUSE: The photoelectric element (e.g., photodiode) in the emitter or receiver is damaged.

REPAIR METHOD: Check the working condition of the photoelectric element, if there is any problem, you need to replace the damaged element.

7. Program malfunction:

POSSIBLE CAUSE: Problems with the control program or electronics of the grating.

REPAIR METHOD: Check the control system to make sure the program is functioning properly. If necessary, reinstall or upgrade the control program.

In summary

When carrying out maintenance work, be sure to follow the maintenance manuals and operating instructions provided by the manufacturer. In addition, regular preventive maintenance is essential to ensure that the safety grating operates properly over the long term. If you are unsure how to deal with a fault or repair, it is advisable to seek professional technical support.

Welcome to contact chyesic to learn more about our products and professional technical support.