Efficiency and safety of safety gratings and safety light curtains in automated warehousing systems

26 Aug 2024 click : 475

26 Aug 2024 click : 475With the continuous development of automation technology, safety gratings and safety light curtains have been widely used in modern warehousing systems to ensure the safety of workers. These two types of security devices have become an indispensable part of automated warehousing systems due to their efficient performance and reliable security.

As for safety grating

A safety grating is a device that detects the entry of people or objects into a predetermined area through continuous monitoring of a beam of light. It usually consists of a transmitter and a receiver, with the beam emitted by the transmitter and the receiver receiving and monitoring whether the beam is obstructed. When someone or an object enters the beam, the safety grating will immediately emit an alarm signal and quickly stop the controlled mechanical equipment to prevent any potential danger from occurring. Compared to traditional physical barriers, safety gratings can provide higher flexibility. It can be customized according to specific needs, adapting to areas of different sizes and shapes without the need for large-scale modifications or adjustments. In addition, the response speed of the safety grating is very fast, usually completing detection and braking within milliseconds, greatly improving safety and work efficiency.

As for safety light curtain

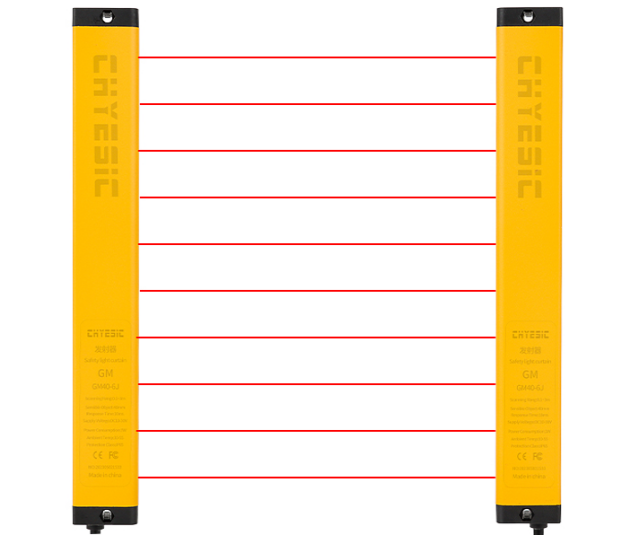

A safety light curtain is another common safety device, similar to a safety grating, but composed of multiple parallel arranged light beams. The spacing between light beams can be adjusted as needed to meet specific safety requirements. When someone or an object enters the beam of light, the safety light curtain will immediately detect it and issue an alarm signal to stop the corresponding mechanical equipment. Compared with safety barriers, safety light curtains have more advantages in coverage area and shading ability, which can provide greater protection for the safety of workers. In addition, security light curtains usually come with advanced features such as zone protection and multi-layer protection, which can be flexibly configured and integrated according to system requirements, providing higher security and flexibility.

As safety devices in automated warehousing systems, safety gratings and safety light curtains play a crucial role in improving work efficiency and ensuring the safety of workers. Firstly, they can effectively monitor and control the behavior of personnel entering hazardous areas, preventing accidents. Secondly, the high response speed of safety gratings and safety light curtains enable mechanical equipment to stop in the shortest possible time, avoiding potential hazards and reducing the risk of injury to personnel and equipment. In addition, the flexibility provided by safety gratings and safety light curtains enable them to adapt to different storage environments and operational needs, providing effective safety protection regardless of size.

In summary, safety gratings and safety light curtains play an important role in the efficiency and safety of automated warehousing systems. They can quickly respond and detect the entry of personnel or objects, issue timely alarm signals and stop mechanical equipment, providing efficient safety protection. By using safety gratings and safety light curtains, enterprises can not only improve work efficiency, but also ensure the safety of employees and reduce the risk of accidents. In the future development of automated warehousing systems, safety gratings and safety light curtains will continue to play an important role in providing reliable guarantees for the safe operation of automated warehousing systems.