As PNP (Positive-Negative-Positive) output configuration sensors, the LM4 and LM5 proximity switches can easily interface with control systems and programmable logic controllers (PLCs). The PNP output type is commonly used in industrial settings and offers versatility in integration with different types of equipment.

Compact volume

High precision of repeated location

Diversified exterior structures

Long service life

Wide voltage range

Many output forms

With short-circuit protection

With inverted connecting protection

Dust proof, vibtation proof, water proof and oil proof

Good performance of anti-interference

High on-off frequency

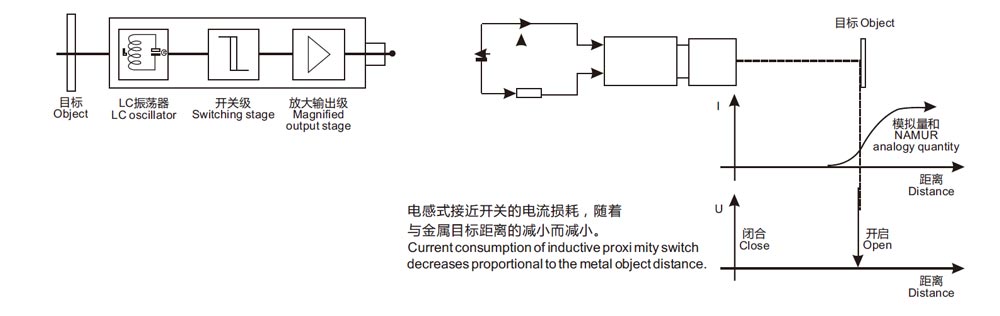

Working principle inductive proximity switch

Inductive proximity switch is composed of three parts: oscillator, switch circuit and magnified output circuit. The oscillator will generate an alternating electric field. When hemetal object approaches this electric field and reaches the induction distance, whirlpool will generate in metal object, resulting in attenuation of vibrati on and then stop. The changeof vibration and stop of oscillator is treated by begid stage magnified circuit and convertedto switching sign, triggering driving con-contact detection.

Application illustration of proximity switch

Features of proximity switch

| Item | Explanation | Features | About detected object |

| the size of detected object and detection distance |

If the detected object is square metal sheet with constant thickness(t=1mm), detect at detection distance X when change its side length dmm.

|

When the detected object is bigger than standard detected object, on the main, the detection distance is constant. According to different machine type, sometimes the features will be different with that mentioned on the left. To through type, the detection object is like cylinder metal bar. |

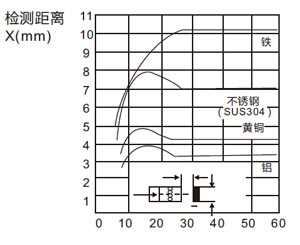

About detected object When the material of detected object is non magnetic metal, the distance of action should deseend. But when the foil material is approximaterly thicker than a.01mm, the detection diatance willbe the same as that of magnetic object. lf the film plating is extremely thin or non-conductive, detection cannot be conducted. The effect of cladding material ,when detected object has cladding material, take note of the changing of detection diatance. |

| the thickness of detected object and detection distance |

Detect at detection distance Xmm (front detector) when change the thickn ess of the assigned standard detected object 1mm.

|

For more than 1mm thick magnetic metal like iron, on the main, the detection distance will not chaneg. |

About ambient weather In order to maintain reliable action and long service life, please avoid the (outdoor) occasion beond the stiplatedambient temperature. Do not drench it with water-soluble cutting lubricant when it is used with cover, althouththeproximity sensor is waterproof. Do not use in the occasion swith chemical agents, especially strong base, acid, nitric acid, hot strong sulfuric acid and so on. |

| the effects resulted from the thickness of detected object and cladding material |

Because the detection to standard detected object will be effected by its shape, size, material, and various caldding material, confirm through detection distance Xmm measurement

|

The effects resulted from detection distance and cladding material of the metal excluded iron will be different according to different machine type. On the main, the machine type which detects all the metals will not be effected by cladding material. |

About maintenance and overhaul In order to keep the proximity sensor to work stably for long time, the ollowing regular examinations should be performed just like general control. 1.Check the installation position of detected object and proximityseensor if any deviation, loosening of deformation exiss. 2.Check the attached wires and connecting parts if any loosening, bad contact or wire breaking off exists. 3.Check if there is any metallic powder accumulation or not. 4.Cherck if the temperature condition and surrounding environment condition are mormal or not. 5.Cherck if the detection distance is normal or not. |

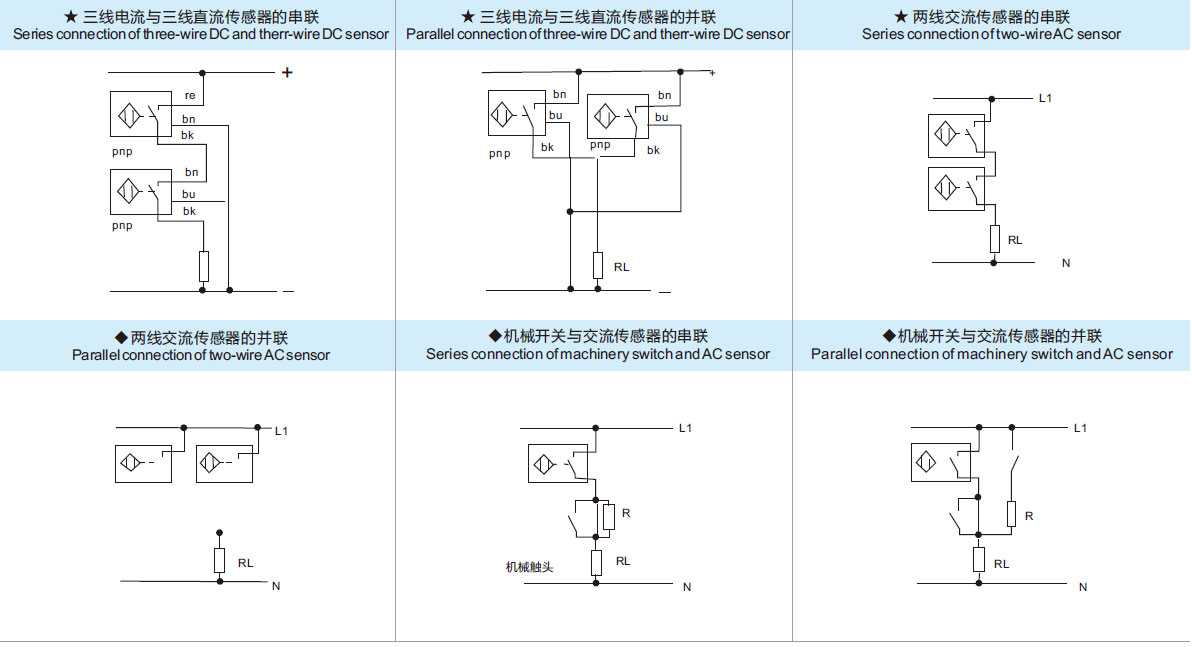

Series Connection And Parallel Connection

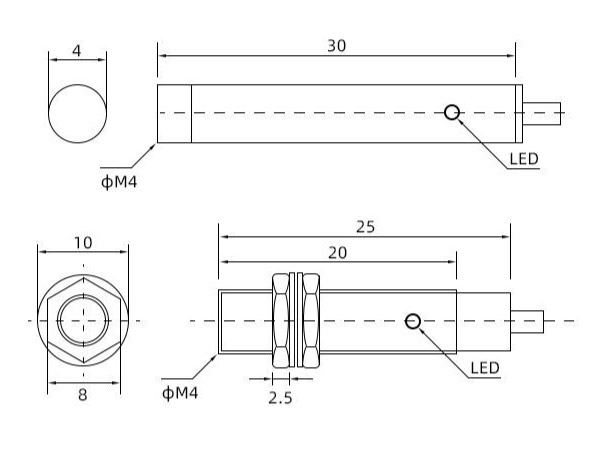

| Model | LM4 | |||

| Dimension |  |

|||

| Sense distance | 1mm±10% | |||

| Flush type | DC10~30VDC | NPN | NO | LM4-3001NA |

| NC | LM4-3001NB | |||

| NO+NC | LM4-3001NC | |||

| PNP | NO | LM4-3001PA | ||

| NC | LM4-3001PB | |||

| NO+NC | LM4-3001PC | |||

| Two-wire system | NO | LM4-3001LA | ||

| NC | LM4-3001LB | |||

| AC90~250VAC | NO | LM4-2001A | ||

| NC | LM4-2001B | |||

| NO+NC | LM4-2001C | |||

| Sense distance | 1mm±10% | |||

| Non-flush type | DC10~30VDC | NPN | NO | LM04-3001NA |

| NC | LM04-3001NB | |||

| NO+NC | LM04-3001NC | |||

| PNP | NO | LM04-3001PA | ||

| NC | LM04-3001PB | |||

| NO+NC | LM04-3001PC | |||

| Two-wire system | NO | LM04-3001LA | ||

| NC | LM04-3001LB | |||

| AC90~250VAC | NO | LM04-2001A | ||

| NC | LM04-2001B | |||

| NO+NC | LM04-2001C | |||

| Output current | DC | 200mA | ||

| AC | / | |||

| Output voltage peak | DC type below 3V、Two wire type below 3.9V、 AC below l0V DC<3V, AC<10V | |||

| Consumption current | DC type 8mA at 12V, 15mA at 24V, AC below 10mA DC<15mA, AC<10mA | |||

| Standard detected object | 6×6×1 (A3 iron) | |||

| Repeatability | 0.01 | |||

| Response frequency | 500Hz | |||

| Ambient temperature | -25℃-+75℃ | |||

| Insulation resistance | 50MΩ | |||

| Shell material | Metal | |||

| Protection grade | IP67 | |||

.jpg)